Learn about us, what we do and how we do it

Stage 1. Initial inspection

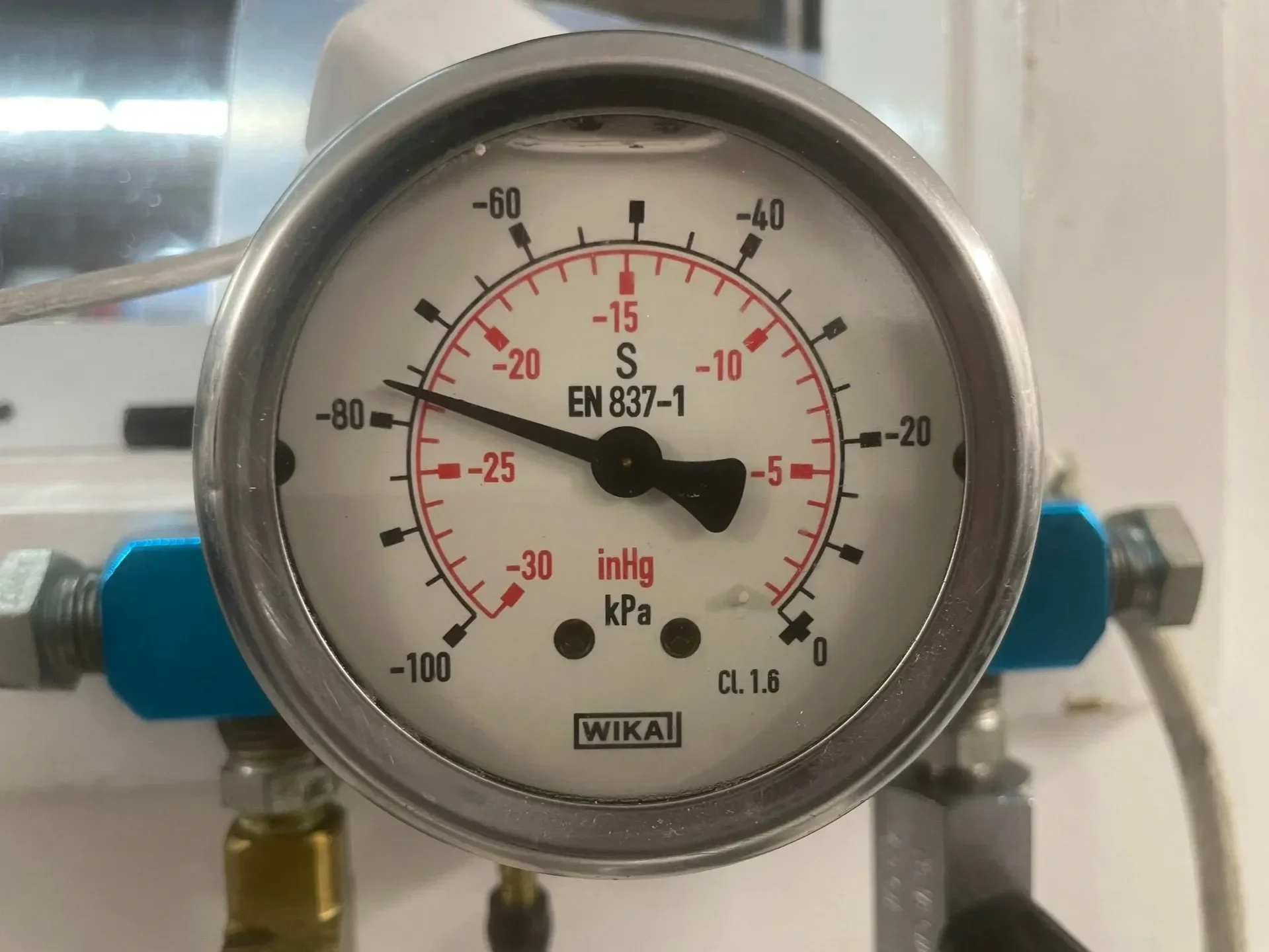

Stage 5. Vacuum test reading

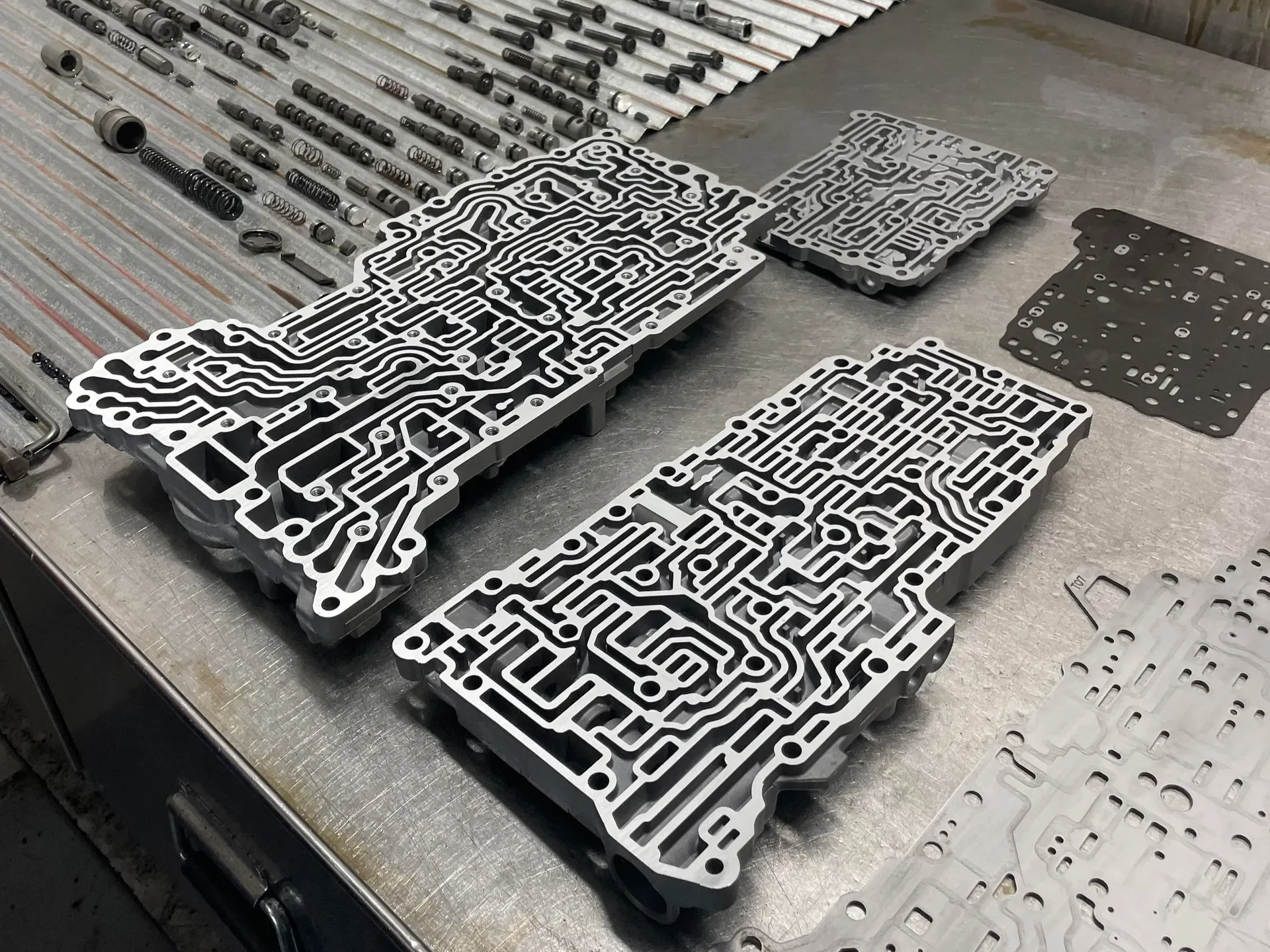

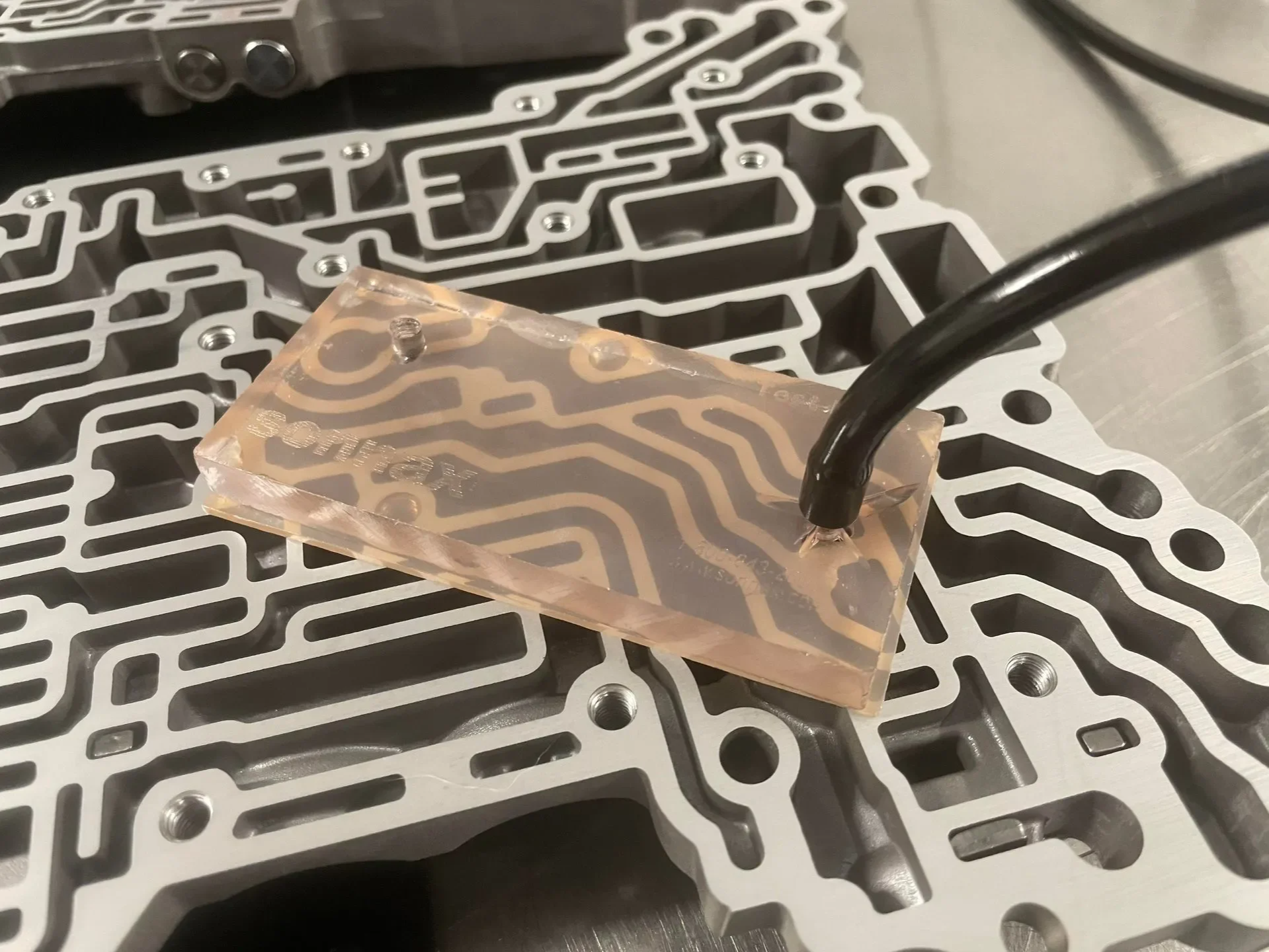

Stage 2. Valve body disassembled

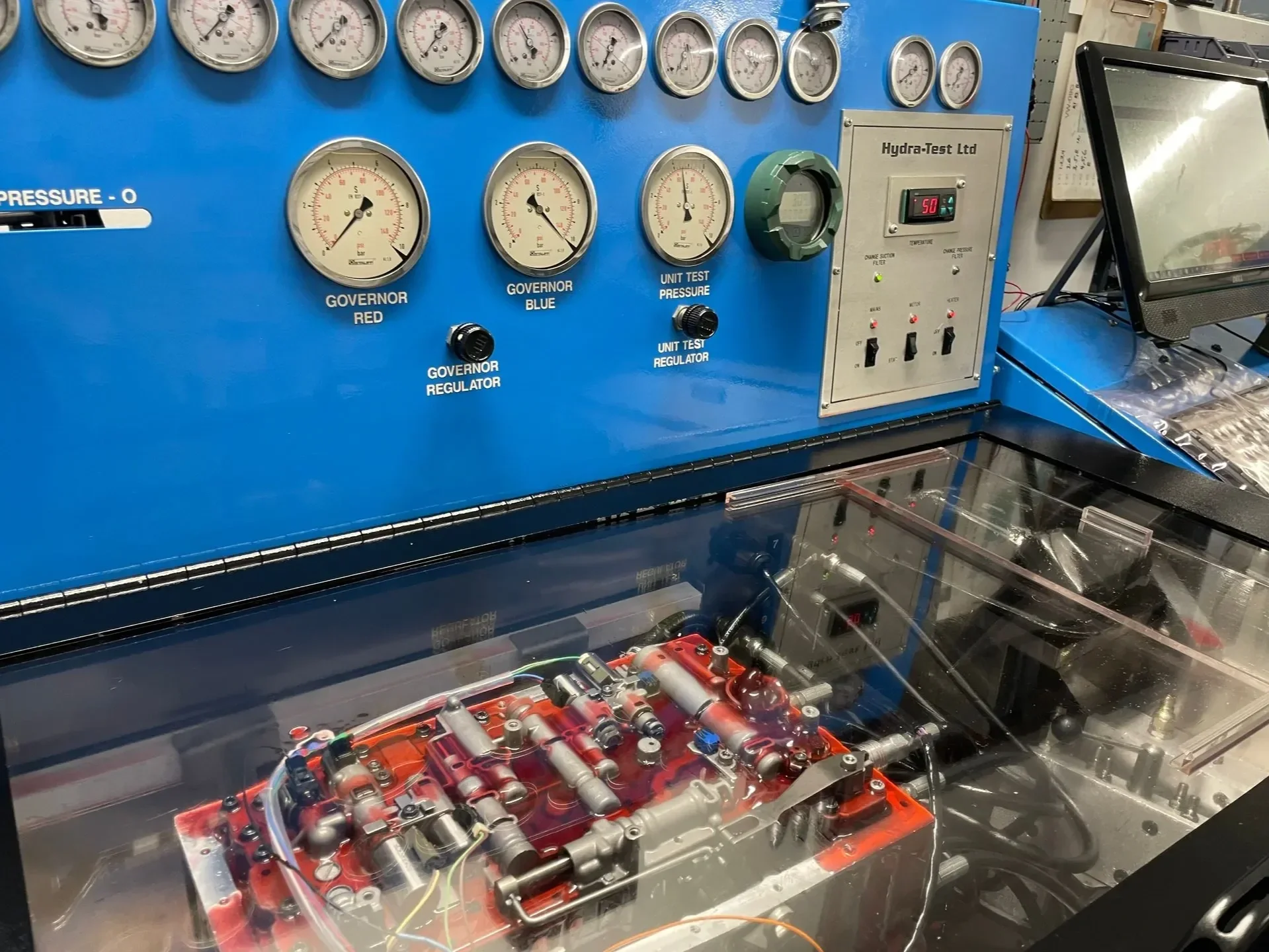

Stage 6. Valve Body Pressure Test

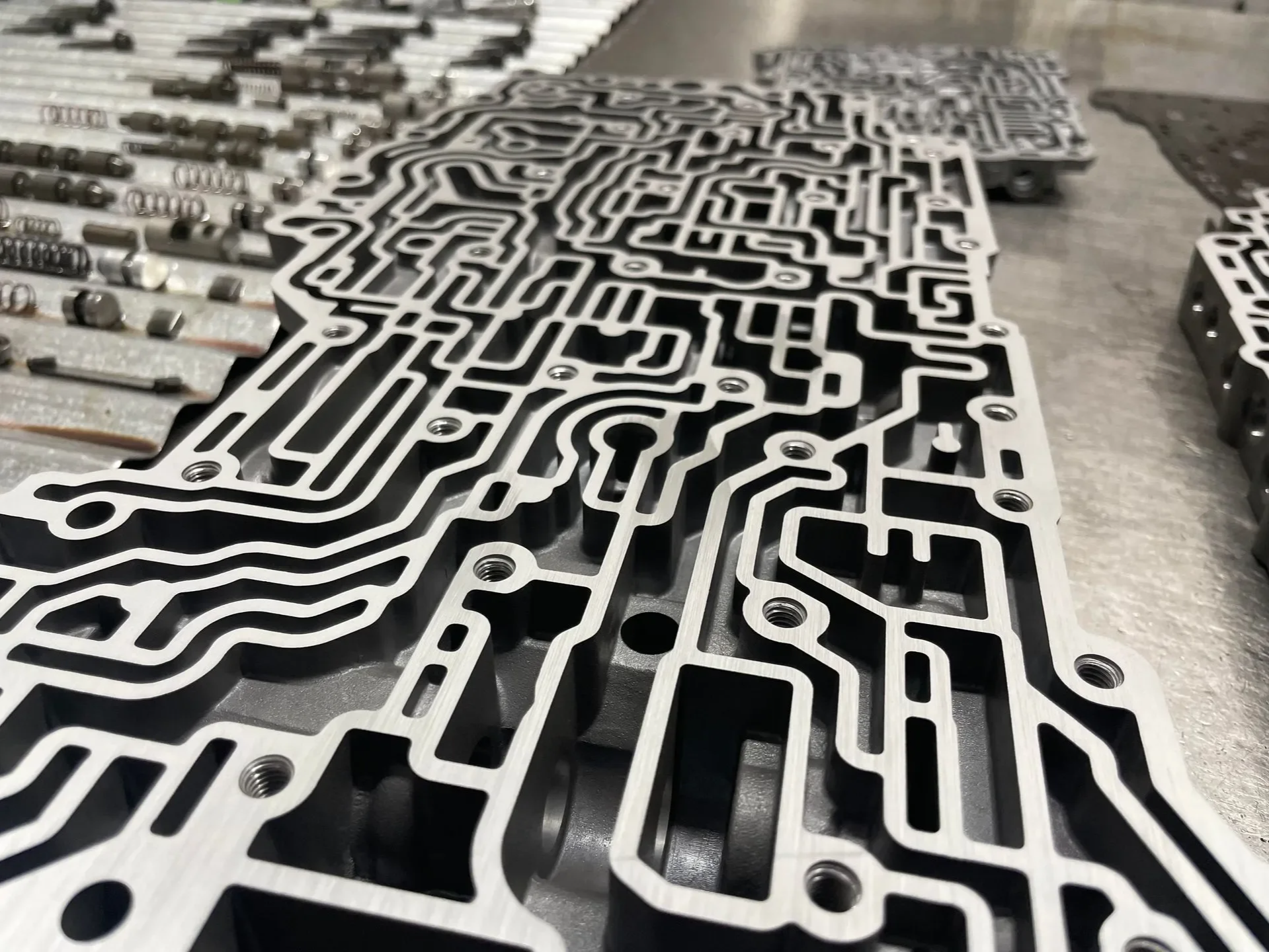

Stage 3. Valve body half resurfaced

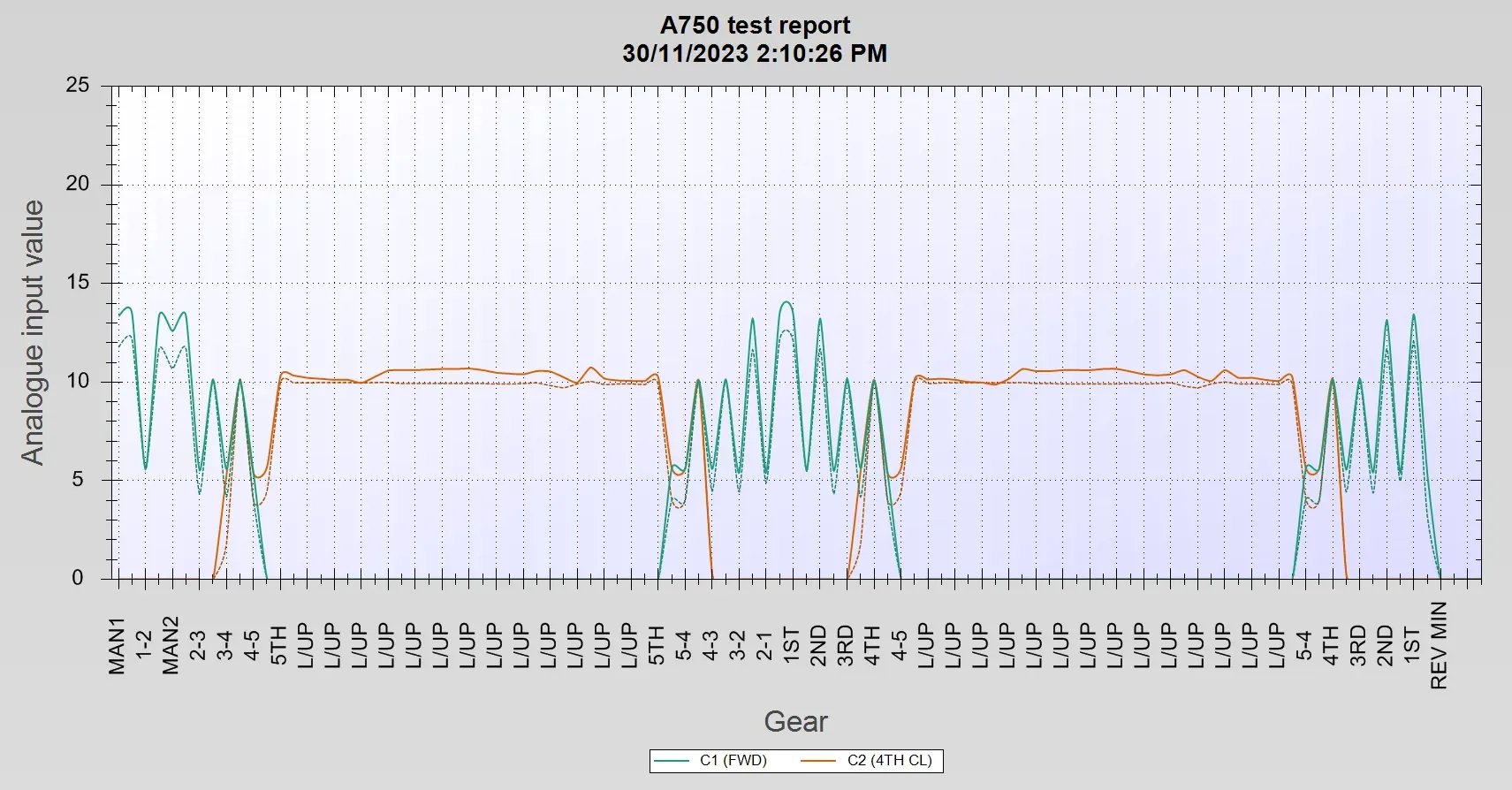

Stage 7. Diagnostics of Pressure Test

Stage 4. Vacuum Test

Stage 8. Pressure Testing Results

The Evolution

With automotive manufacturers on a never-ending quest for improved fuel economy and reduced emissions, the industry has seen a significant shift from conventional 4- 5-6 speed transmissions to 8- 9-10 speed units. Mechanically, transmissions have remained largely the same, still relying on multiple bands, drums and clutches to achieve the desired gear ratios.

Where the real evolution has occurred is within the valve body. As a result of this progression, transmissions have become far more complex and increasingly difficult to diagnose when issues arise.

History and Overview

My name is Nathan McCarthy, and for the past 15 years I have worked for a major supplier to the automatic transmission industry across three different states and in a variety of roles. Throughout that time, I have witnessed firsthand the evolution of transmission technology—an experience that ultimately led me to purchase Valve Bodies Australia (VBOZ).

VBOZ has been operating for over nine years and was founded by Bob Saddleton. Bob owned two transmission specialist businesses in Coffs Harbour and Tamworth, NSW, when he began to notice a shift in the industry. While the UK and the US already had multiple workshops specialising exclusively in valve body reconditioning, Australia had none.

Bob invested heavily in specialist equipment and spent many years researching and developing methods to bench-test valve bodies independently of the transmission. Today, Valve Bodies Australia has a customer base spanning every state and territory in Australia and exports throughout the Asia-Pacific region.

Advantages & Innovations

The ability to bench-test valve bodies and subject them to specific, measurable stress tests—such as heat cycling and variable input line-pressure cycling-has enabled us to identify root-cause issues and significantly reduce costly labour for both transmission specialists and end customers.

What was once an educated guess has now become a proven, reliable solution for valve body failures and malfunctions.

In addition to the move toward higher-gear-ratio transmissions, the industry has also shifted toward non-conventional drivetrains such as CVTs (Continuously Variable Transmissions) and DSG/DCT units (Direct-Shift Gearboxes / Dual-Clutch Transmissions). Although different in design, these transmissions are still controlled by valve bodies and are subject to the same wear and tear as conventional automatics.

In fact, at VBOZ we now repair just as many CVT valve bodies as conventional units. This trend has driven further investment into DSG/DCT capabilities, as we see a growing number of OEM manufacturers transitioning to this platform.

Our Process

Every valve body we service undergoes a structured three-step process designed to eliminate any uncertainty regarding ongoing issues.

Step One: Visual Inspection

The valve body is completely disassembled and visually inspected. This allows us to identify excessive wear in valves and bores, as well as detect any sticking or jammed components.

Step Two: Vacuum Testing

All valves are vacuum-tested to ensure they hold a nominal amount of vacuum. This step provides critical insight into which components require modification or machining to accept oversized valves.

For most rebuilders or transmission specialists, this is where the process ends—reassembly followed by installation and a road test. The problem with this approach is that it assumes everything has been reassembled correctly and that all valves are operating freely and accurately.

With over 100 moving components in some valve bodies, the likelihood of a single part being installed incorrectly is not uncommon. If this occurs, or if a critical circuit or solenoid is underperforming, the diagnostic process becomes costly and time-consuming:

Is it a valve body issue, or is it a mechanical fault within the transmission?

The result is often removal and disassembly all over again.

Step Three: Hydraulic & Functional Testing

This is where our process sets us apart. Solenoids are reconditioned and hydraulically tested independently, followed by full testing of the refurbished valve body. Each unit must pass multiple heat cycles and pressure tests before it is approved.

While there are many additional techniques and refinements within these steps—our “tricks of the trade”—the outcome is clear: a fully validated valve body that eliminates guesswork and can save thousands of dollars in unnecessary labour and repeat repairs.

Many of our customers now treat the valve body as a serviceable replacement component, much like a torque converter or friction plate—often at a fraction of the cost of a new unit.

Summary

As transmissions continue to increase in complexity and the cost of specialised diagnostic equipment rises, Valve Bodies Australia exists to remove uncertainty and provide confidence in the product you deliver.

With coverage across most common makes and models, as well as heavy-duty options, VBOZ is positioned to support the evolving needs of today’s transmission industry